Industry Focused Training - (Lunch & Learn)

Swagelok Industry Focused Training

(Lunch & Learn)

Swagelok Eastern Australia and New Zealand's Industry Focused Training / Lunch and Learn Program consists of information sessions of 30-45 minutes in length that provide attendees with valuable industry knowledge and training.

This training provides you with relevant, up to date, industry training in line with Swagelok's values of customer focus and continuous improvement. Courses can include;

- Pressure Regulator Basics

- Valve Selection

- Corrosion

- Grab Sampling

- Thread Identification

And much more....

With many years of experience working across a broad range of industries, Swagelok can tailor our Industry Focus Training courses to meet your specific training needs.

Pressure Regulators

Pressure Regulators are widely used in industry but often easily misunderstood devices.

This course has been designed to give attendees an overview of the dynamics associates with Pressure Regulators.

Attendees will learn how Regulators work, the different types of Regulators and understand important aspects of using a Pressure Regulator safety and successfully.

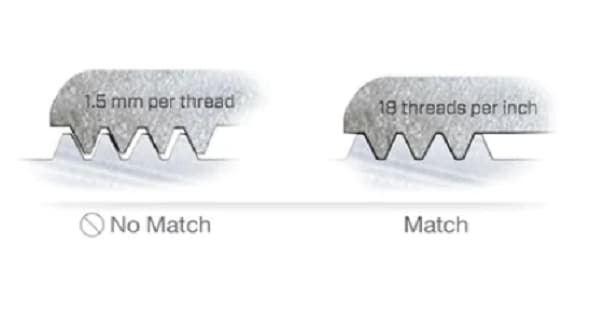

Thread Identification

The Thread Identification course focuses specifically on pipe thread connections like NPT and BSP.

Identifying the correct thread size and type is essential when designing and installing and servicing threaded connections.

This course will help you team identify threads correctly to ensure a leak free and reliable connection in your pressurised system applications.

Corrosion

This course introduces the various catagories of corrosion commonly seen in fluid systems.

We will discuss NACE (National Association of Corrosion Engineers) and developed standards for sour gas environments.

Attendees will be better equipped to identify corrosion and causes of corrosion, providing a fundamental understanding of corrosion and new alloys developed to provide corrosion resistance.

Gas Distribution

Gas Distribution Systems offer standardised Pressure Regulator solutions to aid ease of use.

This course explains the concepts behind Gas Distribution, typical challenges faced and solutions for safer systems.

Attendees will understand how to better design their gas delivery systems and utilise standardised offerings to reduce system modifications, leakage and safety risks.

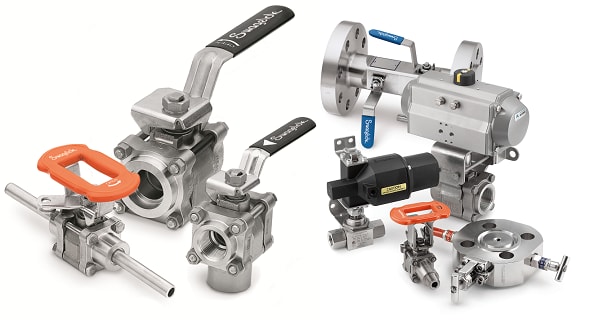

Valve Selection

Improper Valve Selection is the main cause of valve failure or leakage in industry today.

Understanding the five different types of valves available in the market is fundamental to correct valve selection.

Attendees will be equipped with the skills and knowledge need to correctly select a valve, based on system parameters, function and maintenance needs.

Analytical Instrumentation

Analytical Instrumentation helps understand the critical factors associated with sample systems.

You will understand how to have a timely, representative and compatible sampling system design for correct analysis.

Attendees will have a better understanding of sample system design basics, unreliable analyser reading troubleshooting and typical system components.

Grab Sampling

Grab Sampling is critical to ensuring your plant is running efficiently and your product on specification.

This course is designed specifically to help engineers and analyser technicians who design, build and manage Grab Sampling systems.

Attendees will understand basic principles, where to best position sampling points and the various Grab Sampling design options available.

Hose Selection

Companies can spend far too much time and money repairing and replacing Hoses on their plant.

This course is designed to help you get the design aspects correct, as well as correct hose selection, extending hose life.

Attendees will understand how to specify the correct hose, including orientation to aid long term performance, minimising waste and costs.

Process Interface

Process Interface Valves simplify valve connectivity for larger bore, flange type valve connections.

This course will help you understand how to make smooth transitions to reduce leak points and weight in your systems.

Attendees will understand conventional and interface styles, understand the advantages and design considerations with Process Interface Valves.

Cone & Thread

Cone and Thread Fittings can be complicated to understand, when dealing with very high pressures.

This course will help understand components available and installation instructions for fittings up to 60,000 PSI.

Attendees will understand safe component selection, installation practices, tooling required and how to troubleshoot leakage issues.

VCO & VCR Fittings

If you're connecting a fitting multiple times a day, then a Face Seal Fitting like VCO or VCR could be a better solution.

Understanding VCO o-ring fittings and VCR metal gasket fittings will help you better select the right solution for your application.

Attendees will learn about these fitting types, their benefits, how they are used and installed as well as troubleshooting and product care information.