Industry Focused Training - Lunch & Learn

Industry Focused Training

Industry Focused Training provides you with a range of short, 30-45 minute courses on Regulators Basics, Corrosion, Thread Identification and much more.

These courses are delivered onsite to your team, or virtually via webinar, to up-skill your team on the chosen topics. Customers often bundle 2 or 3 of these courses into one training event.

Gain a better understanding of regulators

This Regulator lunch & learn has been designed to give attendees an overview of the dynamics associated with pressure regulators. Having completed this session attendees will be equipped with a better understanding of regulators, making design and selection choices easier. Topics covered include:

• How regulators work

• Characteristics of different regulators

• Pressure reducing versus back pressure

• Loading and sensing element types

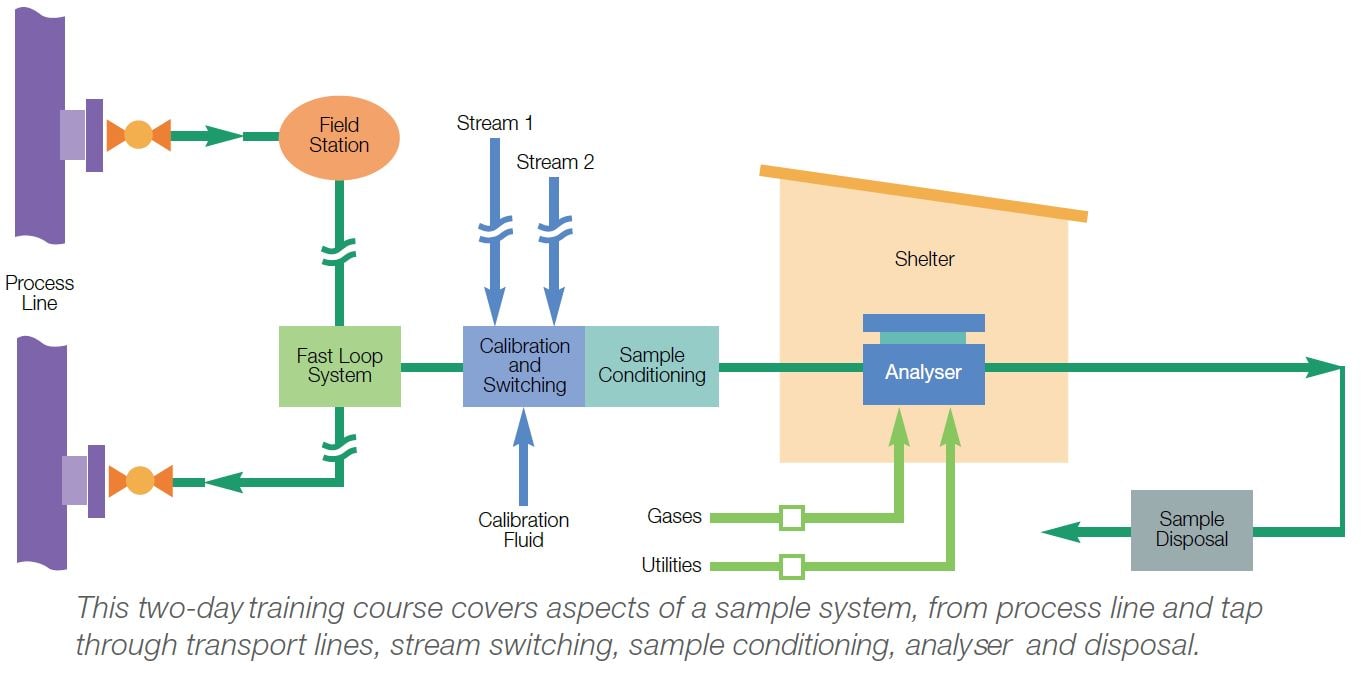

Optimise Your Sampling Systems. Avoid Costly Mistakes.

Our Analytical Instrumentation lunch and learn has been developed to discuss the critical factors associated with good sample system design. Topics covered:

• What is analytical instrumentation ?

• The most common causes of unreliable analyser data

• Three key factors for good sample system design

• Typical sample system components.

Grab Sampling

Providing a background to industry accepted Grab Sampling methods and options depending on product requirements, is the focus of this 1/2 hour informational lunch and learn session. Topics covered:

• Why Grab Sampling?

• Basic principles of grab sampling

• Sampling points - where & why

• Typical grab sample designs

• Selection of the best grab sampling solutions

Thread Identification

The Thread Identification lunch & learn focuses specifically on pipe threads. Identifying the correct thread is essential when designing and installing threaded connections. In an effort to reduce emissions and associated costs, industry demands leak free connections. Crucial to these demands are correctly identified and installed pipe thread connections. Topics included:

Thread terminology - Identification of threads

Installation of the various types of threads

Problems associated with threaded connections

Flexible Hose & Tubing

The Flexible Hose and Tubing lunch & learn has been developed to provide an appreciation of the critical factors associated with the design and selection of flexible hose and tubing systems.

Upon completion of this session, attendees will have a better understanding of the factors that may impact the long term performance and reliability of flexible hose systems. Topics covered include:

• Why use flexible hose and where ?

• Hose core materials

• Construction and options

• Best practice

Process Interface Valves

Process Interface Valve lunch & learn explains how these valves allow for a smooth transition from the process piping system to instrumentation in a single configuration. This system of process interface is being widely used as it provides fewer potential leak points, lower installed weight and a smaller space envelope. Topics covered include:

• Conventional process interface systems

• What are process interface valves

• Advantages over conventional process interface systems

• Applications and design considerations

Valve Selection

The most common cause of valve failure is incorrect selection. The valve selection lunch and learn has been designed to equip participants with the skills and knowledge needed to select the appropriate valve for a specific application. Topics covered include:

• Valve function System parameters

• Valve construction, valve actuation

• Safeguarding and maintenance

Coning and Threading for Medium and High Pressure Products

IPT Series precision medium and high pressure products are designed for working pressures up to 60,000psi. The lunch and learn demonstrates the fundamentals associated with coned and threaded fittings, specifically detailing installation procedures and troubleshooting initiatives.

Topics covered include:

• Component Selection and Identification

• Correct Installation

• Coning and Threading Tools

• Typical Installation Problems

• Troubleshooting

• Safe Working Practices